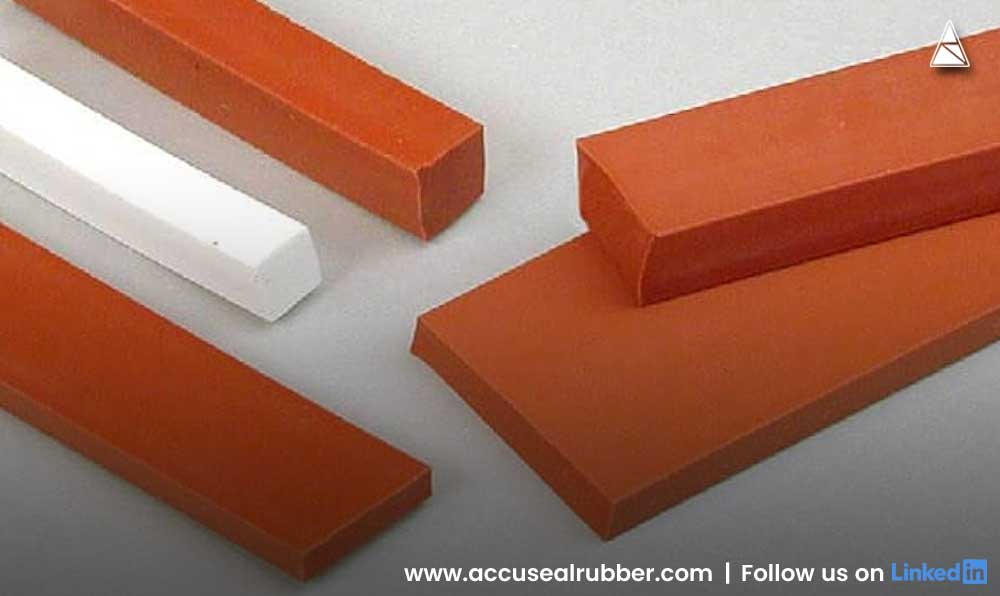

In the world of heavy machinery, where precision and durability are paramount, the right sealing solutions can make or break performance. Rubber square and rectangular seals stand out as indispensable components, ensuring efficiency, reliability, and protection in demanding environments. Whether in construction, mining, or industrial applications, these seals offer unmatched benefits that keep equipment running smoothly.

1. Superior Leak Prevention

One of the most significant advantages of rubber square and rectangular seals is their ability to prevent leaks effectively. The unique geometry of these seals allows for a tighter fit in grooves and cavities, ensuring a robust barrier against fluids, gases, and contaminants. This leak prevention capability is especially crucial in heavy machinery, where exposure to oils, fuels, and hydraulic fluids can lead to costly downtime if not adequately contained.

2. Enhanced Durability in Harsh Environments

Heavy machinery often operates in extreme conditions, including high temperatures, pressure variations, and exposure to chemicals. Rubber seals are known for their resilience and can withstand these harsh environments without losing their sealing properties. Specifically, EPDM, nitrile, and silicone rubber seals are popular choices due to their excellent resistance to heat, chemicals, and abrasion.

Square and rectangular seals are particularly well-suited for heavy equipment as they distribute pressure evenly across their surface, reducing wear and tear and extending their lifespan.

3. Custom Fit and Versatility

Rubber square and rectangular seals can be custom-made to fit specific applications. This flexibility allows manufacturers to tailor the seal’s size, material composition, and hardness to match the needs of different machinery. The ability to customize these seals ensures optimal performance and compatibility, reducing the risk of premature failure.

These seals can also be used in a variety of equipment, from hydraulic presses and pumps to compressors and gearboxes, making them versatile solutions for multiple industries.

4. Shock Absorption and Vibration Dampening

Heavy machinery generates significant vibrations during operation. Rubber seals, due to their inherent elasticity, can absorb shocks and dampen vibrations. This not only protects the machinery’s components from damage but also enhances operator comfort by reducing noise and vibration transmission.

Square and rectangular seals, with their larger surface area, offer superior vibration dampening compared to other seal shapes, providing an added layer of protection for both the equipment and its users.

5. Easy Installation and Maintenance

Rubber seals are known for their ease of installation. Their flexibility allows them to be fitted quickly and securely without the need for specialized tools. Additionally, rubber square and rectangular seals can be easily inspected and replaced during routine maintenance, minimizing equipment downtime.

Their straightforward design also simplifies the maintenance process, as they can be visually inspected for wear and replaced without disassembling complex machinery parts.

6. Cost-Effective Solution

Investing in high-quality rubber square and rectangular seals can save businesses significant costs in the long run. By preventing leaks, reducing downtime, and extending the lifespan of heavy machinery components, these seals help lower maintenance and repair expenses. Moreover, their durability means fewer replacements, contributing to overall cost savings.

7. Compliance with Industry Standards

Many industries have strict regulations and standards regarding the materials used in heavy machinery. Rubber square and rectangular seals are often manufactured to meet these stringent requirements, ensuring compliance with safety, environmental, and performance standards.

This compliance is essential for industries like aerospace, automotive, and oil and gas, where equipment failure can have serious consequences.

8. Improved Energy Efficiency

Effective sealing solutions contribute to energy efficiency in heavy machinery. By minimizing leaks and ensuring optimal fluid containment, rubber seals help maintain consistent pressure levels and reduce energy consumption. This efficiency translates to lower operational costs and a smaller environmental footprint.

9. Resistance to UV and Ozone Exposure

Outdoor machinery is often exposed to UV rays and ozone, which can degrade certain materials over time. Rubber seals, particularly those made from EPDM, are highly resistant to UV and ozone exposure. This makes them ideal for use in outdoor equipment, where long-term durability is critical.

10. Increased Safety and Reliability

In heavy machinery, safety is paramount. Rubber seals play a vital role in maintaining the integrity of hydraulic and pneumatic systems, preventing leaks that could lead to equipment failure or accidents. The reliability of square and rectangular seals ensures that machinery operates as intended, reducing the risk of unexpected breakdowns and enhancing overall safety.

Choosing the Right Rubber Seals for Heavy Machinery

When selecting rubber square and rectangular seals, it’s essential to consider factors such as:

- Material compatibility: Ensure the seal material is suitable for the fluids and temperatures it will encounter.

- Size and shape: Proper sizing is critical for achieving a tight, leak-free fit.

- Operating conditions: Consider the pressure, temperature, and environmental conditions in which the machinery will operate.

Partnering with a trusted supplier can help ensure you get the right seals for your specific needs.

Accuseal Rubber Inc.: Your Trusted Partner in Sealing Solutions

When it comes to finding high-quality rubber seals, trust the experts at Accuseal Rubber Inc. As one of the leading rubber seals manufacturers in the USA, Accuseal Rubber Inc. offers a wide range of custom sealing solutions designed to meet the rigorous demands of heavy machinery. Their commitment to quality, innovation, and customer satisfaction makes them the go-to choice for businesses seeking reliable and durable rubber seals.

Whether you need standard seals or customized solutions, Accuseal Rubber Inc. has the expertise and capabilities to deliver products that enhance performance and extend the life of your equipment.

Conclusion

Rubber square and rectangular seals are vital components for heavy machinery, offering unparalleled advantages in leak prevention, durability, versatility, and cost-effectiveness. Their ability to withstand harsh environments and enhance safety and efficiency makes them an essential choice for industries that rely on robust and reliable equipment.

For businesses seeking top-quality sealing solutions, Accuseal Rubber Inc., a trusted rubber seals manufacturer in the USA, stands ready to meet your needs with precision-engineered products that deliver exceptional performance.

Invest in the right seals today to protect your machinery and ensure long-term success!

Nick Parker

Nick Parker