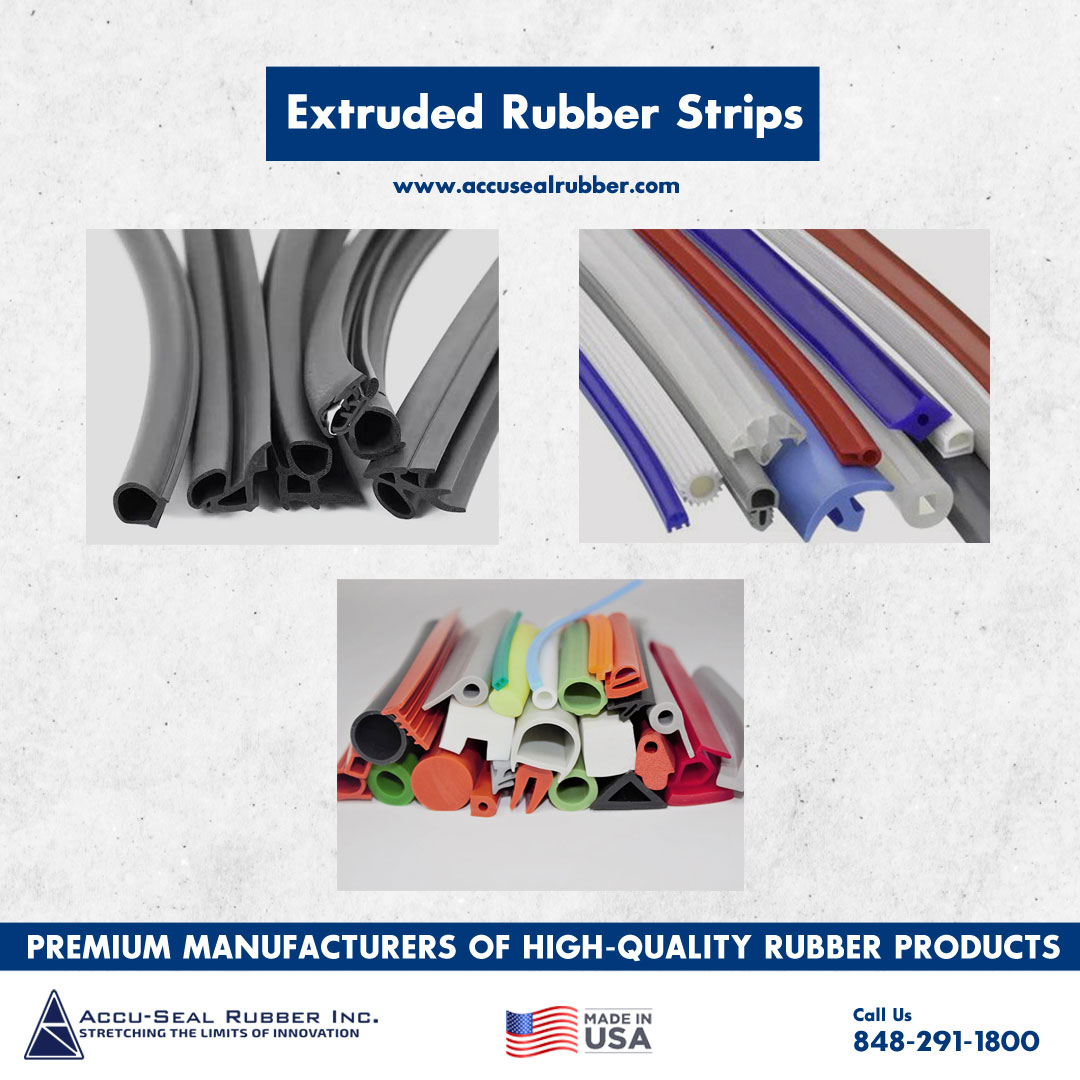

Extruded Rubber Strips

In a world where sealing, protection, and durability are essential for the performance of machines, structures, and various industrial systems, extruded rubber strips provide an invaluable solution. At Accuseal Rubber Inc, we manufacture high-quality extruded rubber strips that are designed to meet the diverse needs of a wide range of industries, including automotive, aerospace, construction, electronics, and more.

Whether you need rubber strips for sealing, cushioning, insulation, or vibration control, our extruded products are available in various dimensions, profiles, and rubber compounds to suit your specific requirements.

What Are Extruded Rubber Strips?

Extruded rubber strips are continuous lengths of rubber that are manufactured through a process called extrusion. During extrusion, rubber compounds are forced through a die with a specific cross-sectional shape to create a continuous piece of rubber with uniform dimensions. This process allows for precise control over the size, shape, and profile of the rubber strips, making them suitable for a wide range of sealing, protection, and insulation applications.

Accuseal Rubber Inc offers extruded rubber strips in various rubber materials, including:

- Silicone Rubber

- EPDM (Ethylene Propylene Diene Monomer)

- Neoprene

- Nitrile Rubber (NBR)

- Natural Rubber

- Viton (FKM)

Each material offers unique characteristics, making our extruded rubber strips suitable for a wide range of temperature, chemical, and environmental conditions.

Key Features and Benefits of Accuseal’s Extruded Rubber Strips

1. Wide Range of Rubber Compounds:

At Accuseal Rubber Inc, we offer extruded rubber strips in a variety of rubber compounds, each tailored to meet specific environmental and mechanical demands. For example:

- Silicone Rubber Strips: Known for their excellent temperature resistance, flexibility, and UV stability, ideal for high-heat or outdoor applications.

- EPDM Rubber Strips: Highly resistant to ozone, UV radiation, and weathering, making them perfect for outdoor sealing applications.

- Neoprene Rubber Strips: Offers excellent resistance to oil, solvents, and weather, suitable for use in environments with exposure to harsh chemicals or outdoor elements.

- Nitrile Rubber Strips: Known for their oil and fuel resistance, ideal for sealing applications in automotive and industrial machinery.

- Viton Rubber Strips: Known for their high chemical and temperature resistance, perfect for sealing applications in demanding chemical environments.

2. Custom Profiles and Dimensions:

Our extrusion process allows for precise customization of the rubber strips to fit your exact specifications. Whether you need standard rectangular strips, U-shaped profiles, or complex cross-sections, Accuseal Rubber Inc can create custom rubber strips tailored to your application’s unique needs. We offer strips in a range of thicknesses, widths, and lengths, ensuring that you get the perfect fit for your sealing, insulation, or protection requirements.

3. Excellent Weather and UV Resistance:

Many of our extruded rubber strips, particularly those made from EPDM and silicone, are highly resistant to ozone, UV radiation, and extreme weather conditions. This makes them ideal for outdoor applications such as window and door seals, automotive weatherstripping, and roofing seals, where long-term exposure to the elements is a concern.

4. Temperature and Chemical Resistance:

Different rubber compounds offer varying levels of temperature and chemical resistance. For example, silicone rubber strips can withstand temperatures from -60°C to 230°C (-76°F to 446°F), making them suitable for high-heat environments, while Viton rubber strips provide excellent resistance to aggressive chemicals, acids, and solvents.

5. Durability and Flexibility:

Our extruded rubber strips are designed to maintain their flexibility and durability even in harsh conditions. This ensures that they remain effective as seals, gaskets, and insulating materials over long periods of use, even in applications involving vibration, compression, or movement. The flexibility of rubber also makes it easier to install the strips in tight spaces or complex configurations.

6. High-Performance Sealing:

One of the primary uses of extruded rubber strips is in sealing applications. Whether used for door and window seals, gasket material, or vibration dampening, our extruded rubber strips provide an airtight, watertight, and dust-proof barrier. This makes them essential for applications where reliable sealing is critical, such as in the automotive, aerospace, and construction industries.

Applications of Extruded Rubber Strips

The versatility and durability of extruded rubber strips make them useful in a wide range of industries and applications. Here are some common uses for our extruded rubber strips:

1. Automotive and Transportation:

In the automotive industry, extruded rubber strips are widely used for weatherstripping, sealing, and vibration control in vehicles. Some of the common applications include:

- Door Seals: Providing a flexible and durable barrier against water, dust, and wind.

- Window Seals: Ensuring a tight seal around automotive windows, preventing air and moisture infiltration.

- Vibration Dampening: Absorbing vibrations and reducing noise in vehicle components.

- Fuel Tank Seals: Nitrile rubber strips are used for fuel and oil-resistant sealing in engines and fuel tanks.

2. Construction and Architecture:

In the construction industry, extruded rubber strips are essential for ensuring long-lasting seals in buildings and structures. Some typical applications include:

- Window and Door Seals: Providing airtight and watertight seals for doors and windows, enhancing energy efficiency and comfort.

- Roofing Seals: EPDM and silicone rubber strips are used for weatherproofing in roofing systems, protecting against water infiltration and environmental damage.

- Expansion Joints: Sealing gaps in concrete structures and bridges to accommodate movement and prevent water ingress.

3. Aerospace and Aviation:

In aerospace applications, where extreme temperatures, pressure, and vibration are common, extruded rubber strips provide reliable sealing and insulation. These strips are used in:

- Cabin Seals: Ensuring airtight seals in aircraft cabins, enhancing passenger safety and comfort.

- Vibration Dampening: Reducing vibration and noise in aircraft components.

- Fuel and Hydraulic Seals: Providing chemical and fuel-resistant sealing in critical aerospace systems.

4. Industrial Machinery:

Extruded rubber strips are used in a variety of industrial machinery and equipment for sealing, insulation, and protection. Examples include:

- Gasket Material: Providing a durable, flexible, and heat-resistant gasket solution for industrial machinery.

- Equipment Seals: Offering protection against dust, moisture, and chemicals in manufacturing environments.

- Vibration Control: Absorbing vibrations and reducing wear on equipment, extending the lifespan of machinery.

5. Electronics and Electrical:

In the electronics industry, extruded rubber strips are used for sealing and insulating electronic components, as well as providing EMI/RFI shielding. Applications include:

- Cable and Wire Insulation: Protecting electrical wiring and cables from moisture, chemicals, and abrasion.

- Sealing Enclosures: Providing weather-resistant seals for electronic enclosures and control panels.

6. Marine and Offshore:

In marine environments, extruded rubber strips are essential for sealing and protecting against harsh weather, saltwater, and UV exposure. Common marine applications include:

- Hatch Seals: Providing watertight seals for boat hatches and doors.

- Window Seals: Offering UV and saltwater-resistant seals for boat windows and portholes.

- Vibration Dampening: Reducing vibrations and wear in marine engines and equipment.

Why Choose Accuseal Rubber Inc for Extruded Rubber Strips?

At Accuseal Rubber Inc, we are committed to delivering high-quality, custom-engineered rubber solutions that meet the unique requirements of our customers. Our extruded rubber strips offer:

- Superior Quality: Manufactured using the finest rubber compounds, ensuring long-lasting performance and reliability.

- Customization: Whether you need specific profiles, dimensions, or material properties, we offer tailored solutions to fit your needs.

- Technical Expertise: Our team of engineers and material specialists is available to provide expert advice and support for selecting the right rubber strip for your application.

- Durability and Performance: Our extruded rubber strips are designed to withstand challenging environments, including exposure to extreme temperatures, chemicals, and mechanical stress.