Extruded Rubber Lip-seals and Gaskets

Accuseal Rubber Inc is a leading manufacturer of high-quality extruded rubber lip-seals and gaskets, designed to provide reliable sealing solutions across diverse industries. From automotive and aerospace to industrial machinery and consumer products, our extruded rubber seals and gaskets are engineered to prevent leaks, protect components from contamination, and ensure optimal performance in demanding environments.

At Accuseal Rubber Inc, we specialize in producing customized sealing solutions that meet the unique requirements of each application. Whether you need standard extruded seals or custom designs, our products offer exceptional performance, durability, and cost-effectiveness.

What Are Extruded Rubber Lip-Seals and Gaskets?

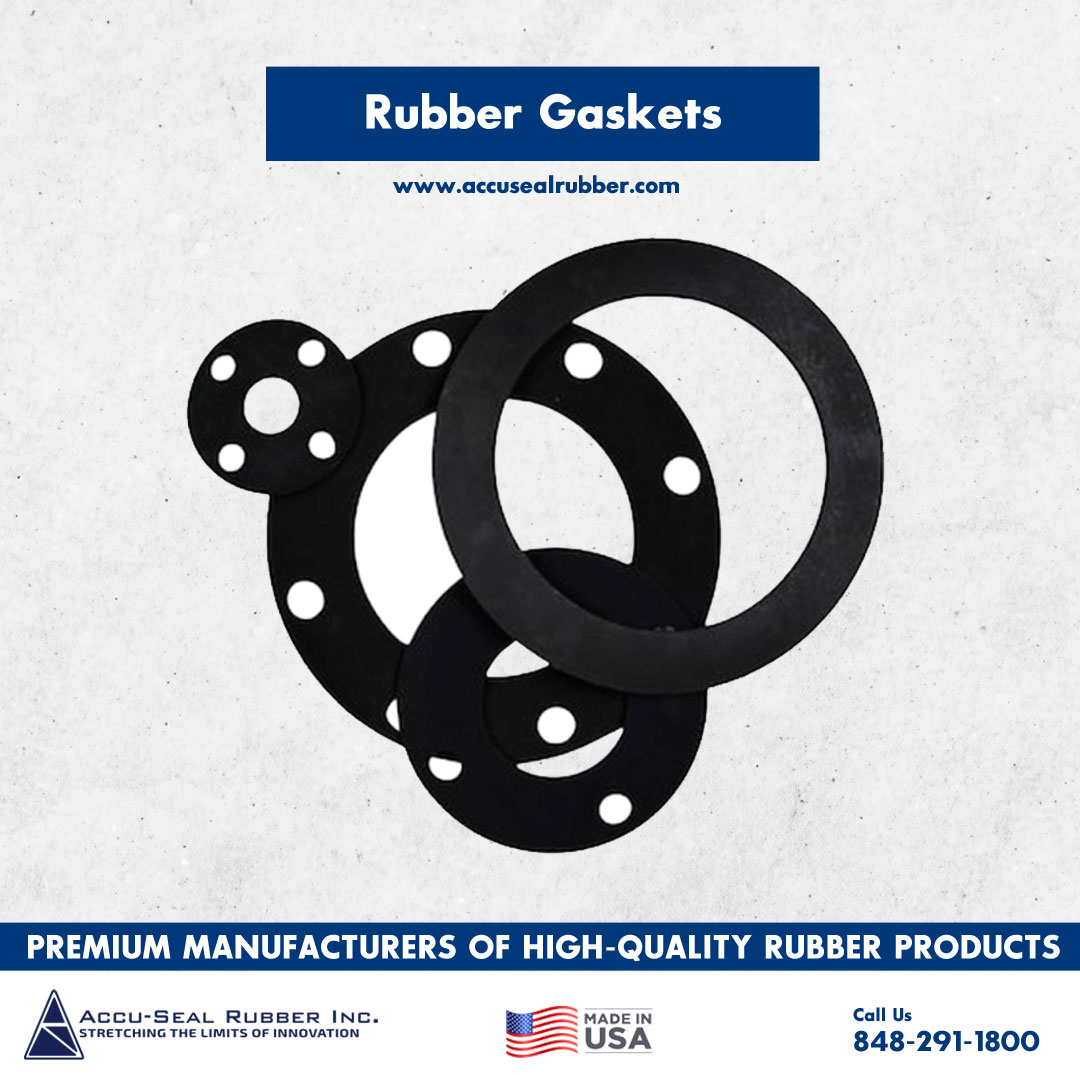

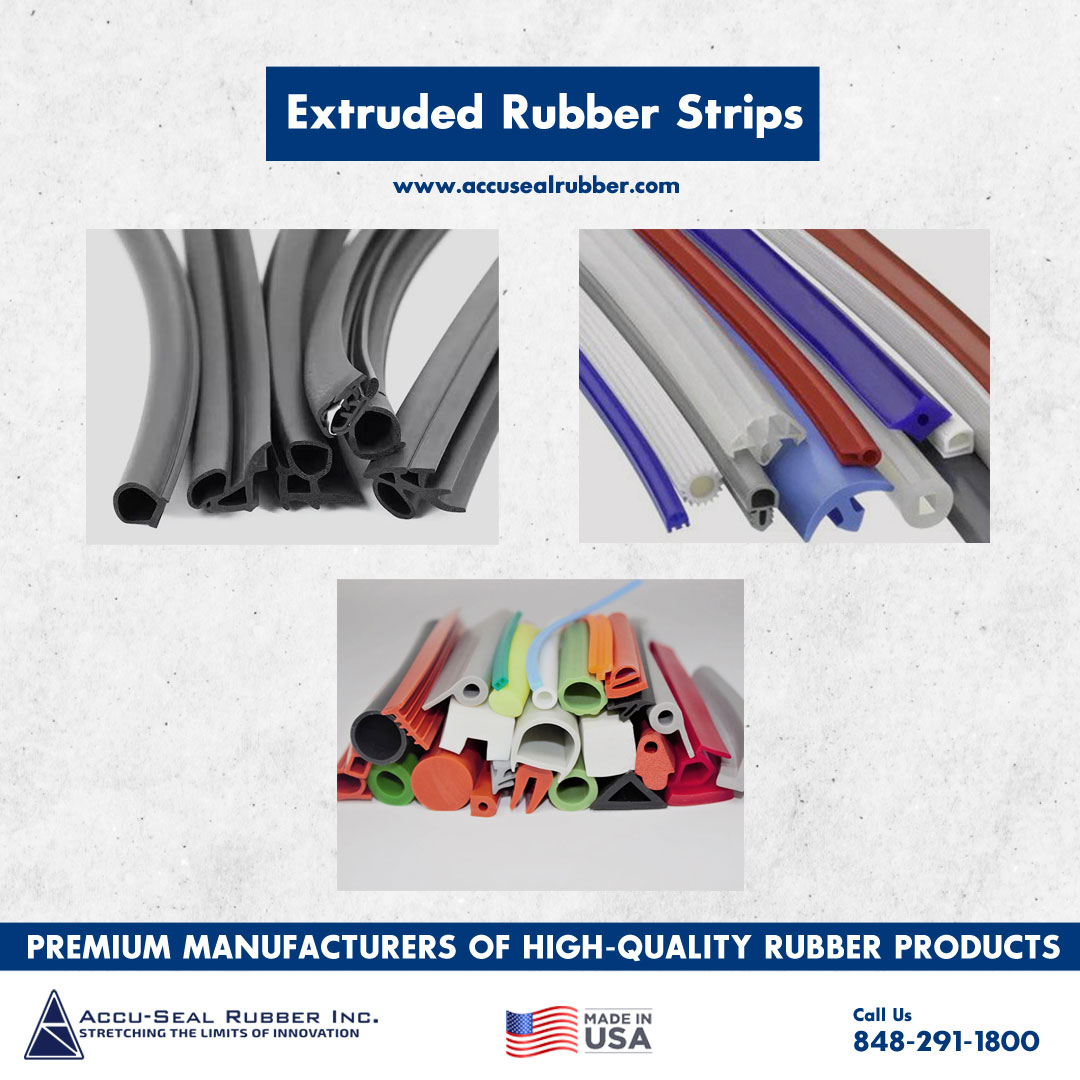

Extruded rubber lip-seals and gaskets are sealing components produced by the extrusion process, where raw rubber material is forced through a die to create a continuous, uniform shape. These seals are typically designed with a lip-shaped profile to provide a tight, flexible seal between two surfaces. Gaskets, on the other hand, are flat sealing rings or sheets used to fill the space between mating surfaces, preventing leaks and ensuring airtight or watertight seals.

At Accuseal Rubber Inc, we use premium-grade elastomers such as silicone, EPDM, nitrile, and neoprene to manufacture lip-seals and gaskets, ensuring excellent performance in terms of temperature resistance, chemical compatibility, and environmental durability. We offer a wide range of extruded profiles, sizes, and materials to meet the diverse needs of our clients.

Key Features and Benefits of Accuseal’s Extruded Rubber Lip-Seals and Gaskets

1. Superior Sealing Performance:

Our extruded rubber lip-seals and gaskets are designed to create a tight, leak-proof seal between two surfaces. The flexible lip design allows for dynamic sealing, meaning that the seal can maintain contact even when the surfaces are in motion or subjected to pressure changes. This feature is particularly important in applications such as automotive door seals or industrial equipment, where maintaining a reliable seal under fluctuating conditions is critical.

2. Resistance to Environmental Factors:

Accuseal Rubber Inc’s extruded rubber seals and gaskets are engineered to withstand exposure to harsh environmental conditions, including UV radiation, ozone, moisture, and extreme temperatures. Whether they are used in outdoor environments, under the hood of a vehicle, or in high-temperature industrial applications, our seals maintain their structural integrity and performance over extended periods of time.

3. Versatility in Materials and Applications:

We offer extruded rubber lip-seals and gaskets in a wide range of elastomers to ensure compatibility with specific application requirements. Each elastomer offers unique properties that make it ideal for different environments:

- Silicone: Offers excellent thermal stability, making it ideal for high-temperature applications.

- EPDM (Ethylene Propylene Diene Monomer): Known for its resistance to UV, ozone, and weathering, making it ideal for outdoor applications.

- Neoprene: Provides excellent oil, chemical, and flame resistance.

- Nitrile (Buna-N): Exceptional resistance to oils, fuels, and chemicals, making it ideal for sealing applications involving fluids.

By selecting the right material, we ensure that our lip-seals and gaskets provide optimal performance for each client’s specific requirements.

4. Customizable Solutions:

At Accuseal Rubber Inc, we recognize that every application has unique sealing requirements, which is why we offer fully customizable solutions. From custom profiles to specific sizes and shapes, we work with our clients to design and manufacture extruded rubber seals and gaskets that meet their exact specifications. Whether you need a complex seal for an automotive application or a simple gasket for industrial machinery, our team is committed to delivering products that meet your needs.

5. Durability and Longevity:

Accuseal’s extruded rubber seals and gaskets are built to last, providing long-lasting durability even in the most challenging environments. Our high-performance elastomers offer excellent resistance to wear, abrasion, and chemical exposure, ensuring that our seals maintain their performance over the lifetime of the application. This durability reduces the need for frequent replacements, minimizing downtime and maintenance costs.

6. Ease of Installation:

Our extruded rubber lip-seals and gaskets are designed for easy installation, ensuring a secure fit between surfaces without requiring complex tools or processes. The flexibility of our rubber materials allows for quick and hassle-free installation, making our seals an ideal choice for applications where time and efficiency are critical.

Applications of Extruded Rubber Lip-Seals and Gaskets

Extruded rubber lip-seals and gaskets are used in a wide variety of industries and applications due to their versatile sealing capabilities. Below are some of the key areas where Accuseal’s extruded seals and gaskets excel:

1. Automotive Industry:

In the automotive industry, extruded rubber seals are used in a wide range of applications, including:

- Door Seals: To provide a tight seal between the vehicle door and frame, preventing water, air, and noise from entering the cabin.

- Trunk and Hood Seals: To prevent dust, water, and other contaminants from entering the vehicle’s trunk and engine compartments.

- Window Seals: To create an airtight barrier between the vehicle’s windows and frame, improving insulation and noise reduction.

Our high-quality seals and gaskets ensure reliable performance in the demanding conditions of automotive environments, including exposure to weather, temperature fluctuations, and mechanical stress.

2. Aerospace Industry:

In aerospace applications, extruded rubber lip-seals and gaskets are critical for ensuring the integrity of aircraft components and systems. Typical aerospace applications include:

- Cabin Pressure Seals: To maintain airtight conditions in the aircraft cabin, ensuring the safety and comfort of passengers and crew.

- Door and Hatch Seals: To prevent leaks and contamination in cargo holds, access hatches, and other critical areas of the aircraft.

Our extruded rubber seals provide the necessary reliability and durability for aerospace applications, where safety and performance are of the utmost importance.

3. Industrial Equipment:

In industrial machinery and equipment, extruded rubber lip-seals and gaskets are used to prevent leaks, protect components, and ensure the efficient operation of systems. Common applications include:

- Hydraulic and Pneumatic Systems: To prevent fluid or air leaks in high-pressure systems, ensuring optimal performance and safety.

- Electrical Enclosures: To provide weatherproof and dustproof seals around electrical enclosures, protecting sensitive components from environmental damage.

Accuseal’s extruded rubber seals and gaskets are designed to withstand the rigors of industrial environments, providing long-lasting protection and performance.

4. Consumer Products:

Extruded rubber lip-seals and gaskets are also widely used in consumer products, including:

- Appliances: To create airtight seals in refrigerators, ovens, and washing machines, ensuring energy efficiency and performance.

- Sporting Goods: To provide durable, flexible seals in outdoor equipment and gear, ensuring protection from moisture, dirt, and other elements.

Our custom-designed seals ensure that consumer products perform reliably and efficiently, providing value and satisfaction to end-users.

Why Choose Accuseal Rubber Inc for Extruded Rubber Lip-Seals and Gaskets?

At Accuseal Rubber Inc, we pride ourselves on delivering high-performance sealing solutions tailored to our clients’ needs. Here are just a few reasons to choose us for your extruded rubber lip-seals and gaskets:

- Expert Manufacturing: Our state-of-the-art extrusion processes ensure consistent quality and precision in every seal we produce.

- Custom Design: We work closely with our clients to create custom seals and gaskets that meet their unique specifications and performance requirements.

- Durability: Our seals are designed to withstand harsh conditions, providing long-lasting performance and protection.

- Technical Support: Our team of experts is always available to provide guidance and support, helping you select the best sealing solution for your application.