Extruded Rubber Double-Bulb Seals and Gaskets

Accuseal Rubber Inc. offers premium Extruded Rubber Double-Bulb Seals and Gaskets, designed for superior performance in demanding sealing applications. With their dual-bulb structure, these seals provide enhanced compression and sealing capacity, offering a robust solution for industries such as automotive, marine, aerospace, construction, and heavy machinery. Double-bulb seals ensure a higher level of airtight and watertight protection, making them ideal for environments where durability and reliability are key.

We have explored the features, benefits, applications, and customization options for Double-Bulb Seals and Gaskets by Accuseal Rubber Inc., highlighting how these seals deliver unmatched performance in complex sealing environments.

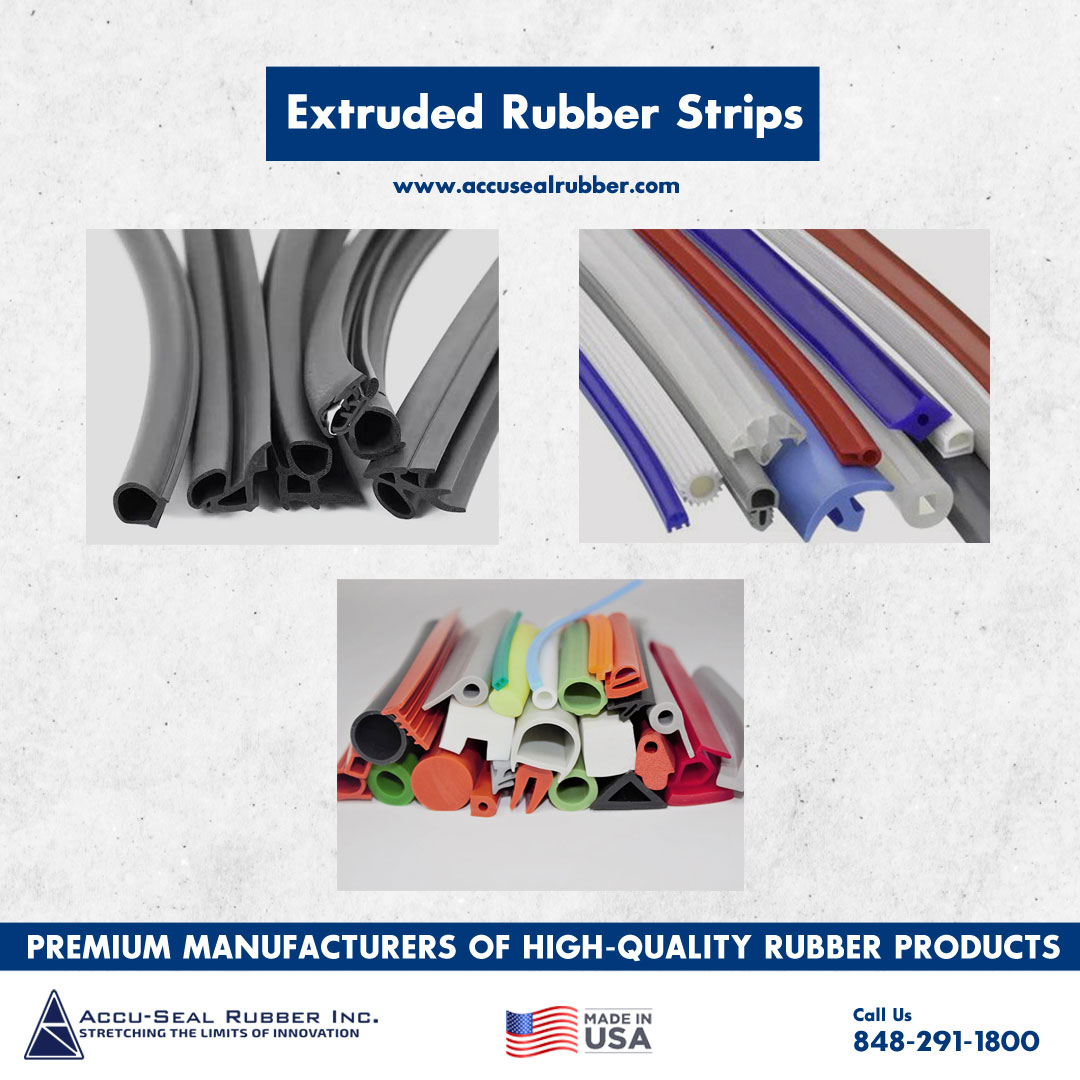

What Are Extruded Rubber Double-Bulb Seals?

Double-bulb seals consist of two compressible bulb-like structures that provide a higher level of sealing performance than single-bulb designs. These seals are engineered to compress easily under pressure and return to their original shape when the pressure is released. The dual-bulb design offers:

- Enhanced Sealing Power: Two bulbs create additional points of contact, ensuring better sealing and compression.

- Greater Flexibility: The flexible structure of the bulbs allows for superior sealing in uneven or complex surfaces.

- Increased Durability: The dual structure provides enhanced resistance to wear and tear in high-pressure applications.

These seals are used in applications that require an extra layer of protection, where standard seals may not be sufficient.

Key Features and Benefits of Accuseal Rubber Double-Bulb Seals

1. Dual Compression Zones for Superior Sealing

The key advantage of double-bulb seals is the dual compression zones, which provide additional sealing points for enhanced performance. These seals compress around gaps or joints, forming an airtight and watertight seal while maintaining excellent recovery properties. This makes them ideal for applications where extra protection against dust, water, air, and noise is essential.

2. Versatility and Adaptability

Accuseal Rubber’s double-bulb seals can be extruded in a variety of materials, profiles, and sizes to suit specific applications. Whether you need seals for low-pressure or high-pressure environments, we can tailor them to meet your exact needs. Our double-bulb seals are widely used in a range of industries, from automotive weatherstripping to industrial enclosure seals.

3. Resistance to Environmental Factors

Double-bulb seals are designed to provide long-lasting resistance to various environmental conditions. Whether it’s exposure to sunlight, ozone, extreme temperatures, or harsh chemicals, our seals maintain their structural integrity and performance. The materials used, such as EPDM, neoprene, and silicone, are selected for their resilience and durability in different environments:

- EPDM Rubber: Outstanding UV, ozone, and weather resistance, suitable for outdoor applications.

- Neoprene Rubber: Good resistance to oil, chemicals, and weathering.

- Silicone Rubber: Excellent thermal stability, performing well in high and low-temperature environments.

4. Shock Absorption and Vibration Dampening

Double-bulb seals are excellent at absorbing vibrations and dampening shocks, protecting equipment from wear and minimizing noise transmission. This feature is critical in applications such as automotive, heavy machinery, and marine environments, where vibration control is essential for smooth operation and longer component lifespan.

5. Customizable Designs for Various Applications

At Accuseal Rubber Inc., we offer customized extruded double-bulb seals based on your specific application requirements. Whether you need a unique profile, size, or material composition, our manufacturing capabilities allow us to design a seal that fits perfectly in your application. We can also provide a range of mounting options, including adhesive-backed or push-fit designs for ease of installation.

Applications of Double-Bulb Seals and Gaskets

The versatility and enhanced sealing properties of double-bulb seals make them suitable for a variety of industries and applications. Below are some common uses:

1. Automotive and Transportation

Double-bulb seals are widely used in the automotive industry to provide superior weatherproofing and sealing solutions. Common automotive applications include:

- Car Door Seals: The dual-bulb structure offers improved sealing around car doors, preventing dust, water, and noise from entering the vehicle cabin.

- Trunk and Hood Seals: Ensures a watertight and airtight seal for trunks and hoods, protecting the interior from environmental damage.

- Sunroof and Window Seals: Provides leak-proof sealing around sunroofs and windows, even in extreme weather conditions.

- Vibration and Noise Dampening: Used in various automotive components to minimize noise and absorb vibrations during vehicle operation.

2. Marine and Watercraft

In the marine industry, double-bulb seals offer protection against water ingress and corrosion, making them a reliable choice for:

- Boat Hatch Seals: Creating watertight seals around hatches to prevent water from entering the boat.

- Window and Porthole Seals: Providing durable seals that withstand saltwater, UV exposure, and constant flexing in marine environments.

- Cabin Door Seals: Ensuring a secure, weather-resistant seal around doors and other access points, maintaining comfort and protection.

3. Industrial Equipment and Machinery

In industrial settings, double-bulb seals are used for sealing and vibration control. Typical applications include:

- Machinery Enclosure Seals: Providing secure seals around equipment enclosures to protect sensitive components from dust, moisture, and other contaminants.

- Vibration Dampening: Reducing mechanical vibrations in heavy machinery, prolonging equipment life and improving operational efficiency.

- Access Panel Seals: Ensuring a tight seal around access panels and doors to protect internal components.

4. Aerospace

In aerospace applications, where lightweight materials and high-performance seals are critical, double-bulb seals offer reliable protection:

- Cabin Door Seals: Creating airtight seals around cabin doors to maintain pressure and prevent air leakage.

- Cargo Compartment Seals: Protecting cargo from dust, moisture, and temperature fluctuations, while also offering vibration isolation.

- Vibration Control: Used in various aerospace components to reduce vibrations and enhance passenger comfort.

5. Construction and Architectural Sealing

Double-bulb seals provide effective sealing solutions in construction and architectural projects. Common uses include:

- Window and Door Seals: Providing a durable, airtight, and watertight seal for residential and commercial windows and doors.

- Roof Seals: Ensuring leak-proof sealing in roofing systems, protecting structures from water infiltration.

- Expansion Joint Seals: Sealing expansion joints in large structures to accommodate movement and maintain protection against water and debris.

Materials for Extruded Rubber Double-Bulb Seals

At Accuseal Rubber Inc., we offer a wide range of materials for our double-bulb seals, each suited to specific environmental conditions and performance requirements. Some popular material choices include:

- EPDM (Ethylene Propylene Diene Monomer): Known for its excellent resistance to weather, UV, ozone, and temperature extremes, EPDM is a popular choice for outdoor applications such as weatherstripping, automotive, and construction seals.

- Silicone Rubber: Offers outstanding heat and cold resistance, with the ability to perform in temperatures ranging from -65°C to 250°C, making it ideal for high-temperature applications in aerospace, automotive, and industrial settings.

- Neoprene Rubber: Combines weather, oil, and chemical resistance, making it suitable for marine, automotive, and industrial environments where exposure to harsh substances is common.

- Nitrile Rubber (NBR): Known for its resistance to oils and chemicals, nitrile is frequently used in automotive and industrial applications involving exposure to fuels, oils, and other substances.

Custom Extrusion for Double-Bulb Seals and Gaskets

Accuseal Rubber Inc. specializes in custom extrusion, allowing you to specify exact design requirements for your double-bulb seals. Whether you need specific dimensions, a custom profile, or specialized materials, our expert team can deliver solutions that meet your unique sealing needs. Customization options include:

- Profile Shape: Select from a range of standard or custom profiles to suit your application.

- Material Selection: Choose from EPDM, silicone, neoprene, and other materials to ensure the best performance in your specific environment.

- Attachment Methods: We offer a variety of attachment options, including adhesive-backed, push-fit, or mechanical fastening designs for easy installation.

Why Choose Accuseal Rubber Inc. for Double-Bulb Seals and Gaskets?

Accuseal Rubber Inc. is a trusted provider of high-quality rubber sealing solutions, including Extruded Rubber Double-Bulb Seals and Gaskets. When you work with us, you can expect:

- Superior Quality: We use only the highest-quality materials, ensuring long-lasting and reliable sealing performance.

- Custom Solutions: Our ability to customize designs and materials ensures you get the perfect seal for your application.

- Expert Engineering Support: Our experienced team is ready to help you find the ideal sealing solution, whether it’s a standard product or a custom design.

- Durability and Reliability: Our double-bulb seals are engineered for durability, offering long-term sealing and protection in harsh environments.