Extruded Rubber Bulb Seals and Gaskets

In industries where superior sealing performance is crucial, Extruded Rubber Bulb Seals and Gaskets provide an effective, flexible, and reliable solution. Accuseal Rubber Inc. specializes in manufacturing high-quality bulb seals that are designed to create airtight, watertight, and vibration-resistant seals in a wide range of applications. Whether it’s for automotive doors, marine hatches, industrial equipment, or window seals, our extruded rubber bulb seals are engineered to perform under challenging conditions, ensuring long-lasting protection.

This comprehensive guide covers the features, benefits, applications, and materials used in the production of Accuseal Rubber Inc.’s Rubber Bulb Seals and Gaskets.

What Are Extruded Rubber Bulb Seals and Gaskets?

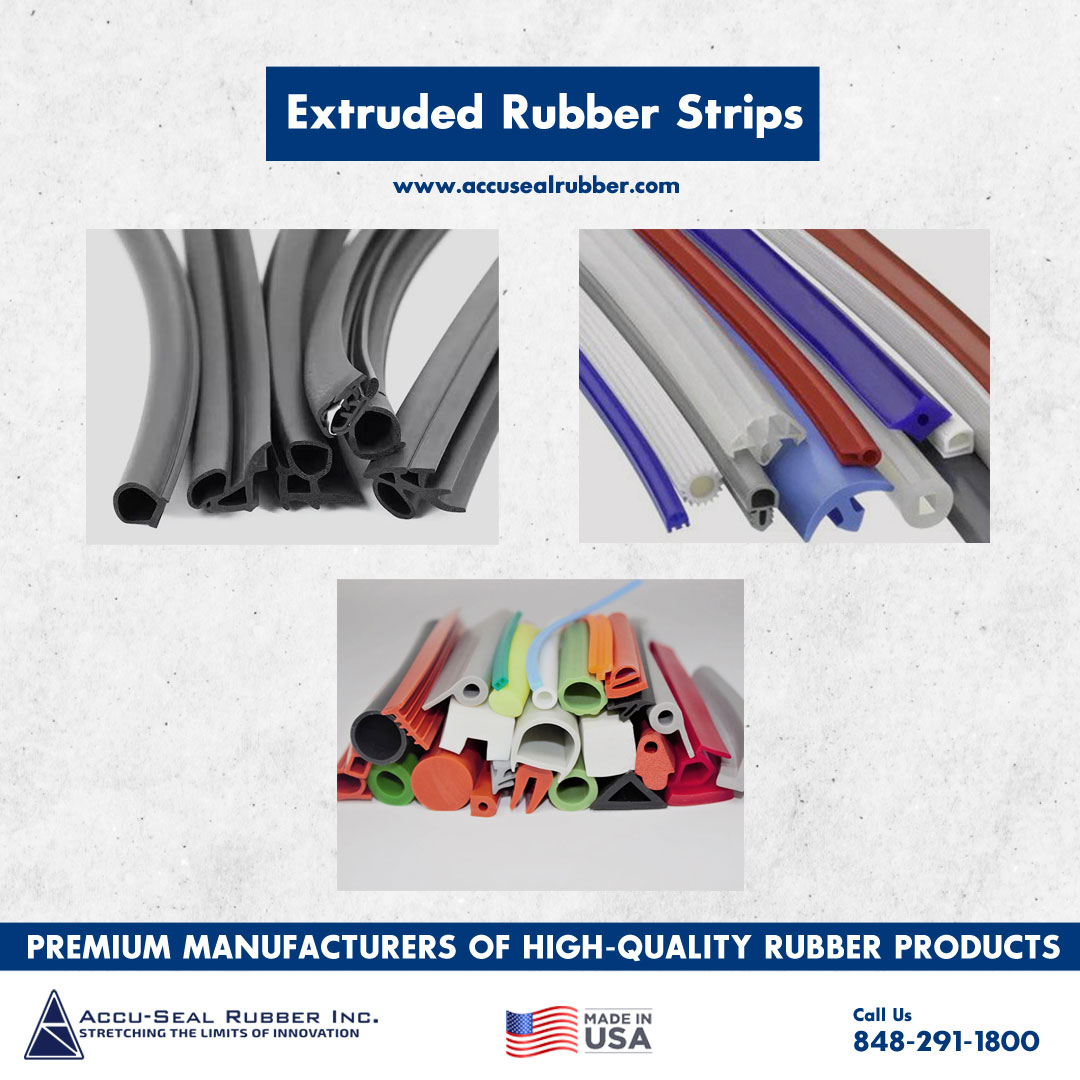

Bulb Seals are flexible rubber components designed with a bulb-shaped sealing area that compresses to create a secure seal between two surfaces. The extruded design allows for precise dimensional control and customization based on specific application requirements. These seals are commonly used for:

- Weatherstripping

- Vibration Dampening

- Noise Reduction

- Shock Absorption

Bulb seals are highly versatile and can be designed in different sizes, profiles, and materials to meet various sealing needs. The bulb section offers flexible compression, while the attachment base provides a secure installation method, making these seals suitable for both static and dynamic applications.

Key Features and Benefits of Accuseal Rubber Bulb Seals and Gaskets

1. Superior Compression and Sealing Ability

One of the standout features of rubber bulb seals is their exceptional compression and recovery properties. The bulb portion easily compresses under pressure to create a snug, airtight seal that prevents the infiltration of water, dust, air, or noise. When pressure is relieved, the bulb returns to its original shape, ensuring long-term durability and reliable sealing performance.

2. Weather and Environmental Resistance

Accuseal Rubber Inc. produces weather-resistant bulb seals that are designed to withstand harsh environmental conditions. Whether you need protection from UV radiation, ozone, saltwater, or extreme temperatures, our bulb seals are manufactured from high-performance rubber materials, ensuring that they perform exceptionally well in both outdoor and indoor applications.

Materials used in our bulb seals include:

- EPDM Rubber: Known for its excellent weather, UV, and ozone resistance, perfect for outdoor sealing applications.

- Silicone Rubber: Withstands extreme temperature ranges, making it ideal for high-heat environments such as automotive or aerospace settings.

- Neoprene Rubber: Offers good chemical, oil, and weather resistance, making it suitable for industrial and marine applications.

3. Versatile and Customizable Designs

At Accuseal Rubber Inc., we understand that each application has unique requirements, which is why we offer customizable extrusion profiles for our bulb seals and gaskets. Whether you need a specific size, shape, or material, our extruded seals can be tailored to your exact specifications, ensuring a perfect fit and optimal sealing performance. We also offer various attachment options, including adhesive-backed, push-fit, and mechanical fastening designs, for easy installation.

4. Vibration Dampening and Noise Reduction

In addition to sealing, bulb seals provide excellent vibration dampening and noise reduction properties. The flexible rubber bulb absorbs mechanical vibrations, reducing wear and tear on equipment, and minimizing noise transmission. This makes them ideal for use in automotive, marine, and industrial machinery, where vibration control is critical for operational longevity and comfort.

5. Durable and Long-Lasting

Our bulb seals are engineered to provide long-lasting sealing solutions even in high-demand environments. The rubber compounds used in the manufacturing process are designed for durability, ensuring the seals maintain their integrity and sealing properties even after years of exposure to harsh conditions or repeated use.

Applications of Rubber Bulb Seals and Gaskets

Extruded rubber bulb seals and gaskets offer versatility and durability, making them ideal for a variety of industrial, automotive, and commercial applications. Here’s an overview of some common uses:

1. Automotive and Transportation

Rubber bulb seals are extensively used in the automotive industry for weatherproofing and sealing purposes. Applications include:

- Car Door Seals: Ensuring an airtight and watertight seal around vehicle doors, preventing dust, water, and noise from entering the cabin.

- Trunk and Hood Seals: Providing a flexible yet secure seal for automotive trunks and hoods, protecting the interior from environmental factors.

- Sunroof Seals: Offering a durable, leak-proof seal around sunroofs, preventing water and air leakage.

- Vibration and Noise Dampening: Absorbing vibrations and reducing noise in various automotive components.

2. Marine and Watercraft

In marine applications, bulb seals are essential for preventing water ingress and protecting against corrosion. Applications include:

- Boat Hatch Seals: Providing a watertight and weather-resistant seal around marine hatches, protecting the interior from water damage.

- Window and Porthole Seals: Offering UV and saltwater-resistant seals for boat windows and portholes.

- Cabin Door Seals: Ensuring an airtight seal for cabin doors, enhancing comfort and preventing water or air leaks.

3. Aerospace

Bulb seals are used in aircraft applications where lightweight, durable, and high-performance sealing is required. Aerospace applications include:

- Cabin Door Seals: Creating airtight seals around aircraft cabin doors to maintain cabin pressure and prevent air leakage.

- Cargo Compartment Seals: Protecting cargo areas from dust, moisture, and temperature fluctuations.

- Vibration Isolation: Reducing vibrations in critical aerospace components, increasing operational reliability and comfort.

4. Industrial Equipment and Machinery

In industrial environments, bulb seals provide critical sealing and vibration control for various equipment. Common uses include:

- Enclosure Seals: Creating secure seals for machinery enclosures, protecting sensitive components from dust, moisture, and contaminants.

- Equipment Seals: Sealing doors, panels, and access points in industrial machinery to ensure protection against dust and water.

- Vibration and Noise Control: Absorbing vibrations in industrial equipment, reducing wear, noise, and increasing operational efficiency.

5. Construction and Architecture

In the construction industry, rubber bulb seals provide sealing solutions for buildings and structures. Typical applications include:

- Window and Door Seals: Offering weatherproof and airtight sealing for residential and commercial windows and doors, ensuring energy efficiency and protection against environmental elements.

- Roof Seals: Preventing water infiltration in roofing systems, providing long-lasting weatherproofing.

- Expansion Joint Seals: Sealing expansion joints in bridges and large structures, accommodating structural movement while maintaining protection against water and debris.

6. Commercial and Residential Sealing

For everyday sealing solutions, rubber bulb seals are frequently used in residential and commercial settings. Common uses include:

- HVAC Seals: Providing airtight seals in HVAC systems, ensuring energy efficiency and preventing air leaks.

- Door Gaskets: Sealing entry doors, garage doors, and other access points to prevent drafts and energy loss.

Custom Extrusion Options for Rubber Bulb Seals and Gaskets

Accuseal Rubber Inc. offers extensive customization options to ensure that your bulb seals and gaskets meet the exact specifications of your application. Our custom extrusion capabilities include:

- Material Selection: Choose from a variety of rubber compounds, including EPDM, silicone, neoprene, nitrile, and more.

- Profile Design: We offer a wide range of standard profiles, or we can work with you to design a custom profile to suit your specific needs.

- Size and Length: Our extrusion process allows for flexibility in size, shape, and length, ensuring the perfect fit for your project.

- Adhesive Backing or Mounting Options: Choose from adhesive-backed seals or various mounting options, including mechanical fasteners and push-fit designs.

Why Choose Accuseal Rubber Inc. for Your Rubber Bulb Seals and Gaskets?

At Accuseal Rubber Inc., we pride ourselves on providing high-quality, durable, and customized sealing solutions for a wide range of industries. When you choose our Rubber Bulb Seals and Gaskets, you benefit from:

- Superior Quality Materials: Our rubber compounds are selected for their durability, flexibility, and resistance to environmental factors.

- Custom Design and Fabrication: We offer a wide range of standard and custom profiles, ensuring a perfect fit for your application.

- Expert Engineering Support: Our team of engineers and material specialists is here to provide guidance and recommendations to ensure you get the right seal for your project.

- Durable Performance: Our bulb seals are designed to withstand the most demanding conditions, ensuring long-lasting sealing performance.